I managed the Industrial HW team during the group’s beginnings. We worked closely with the sales team, going onsite with customers, researching needs, and quickly iterating products from 0 to 1 to test product market fit.

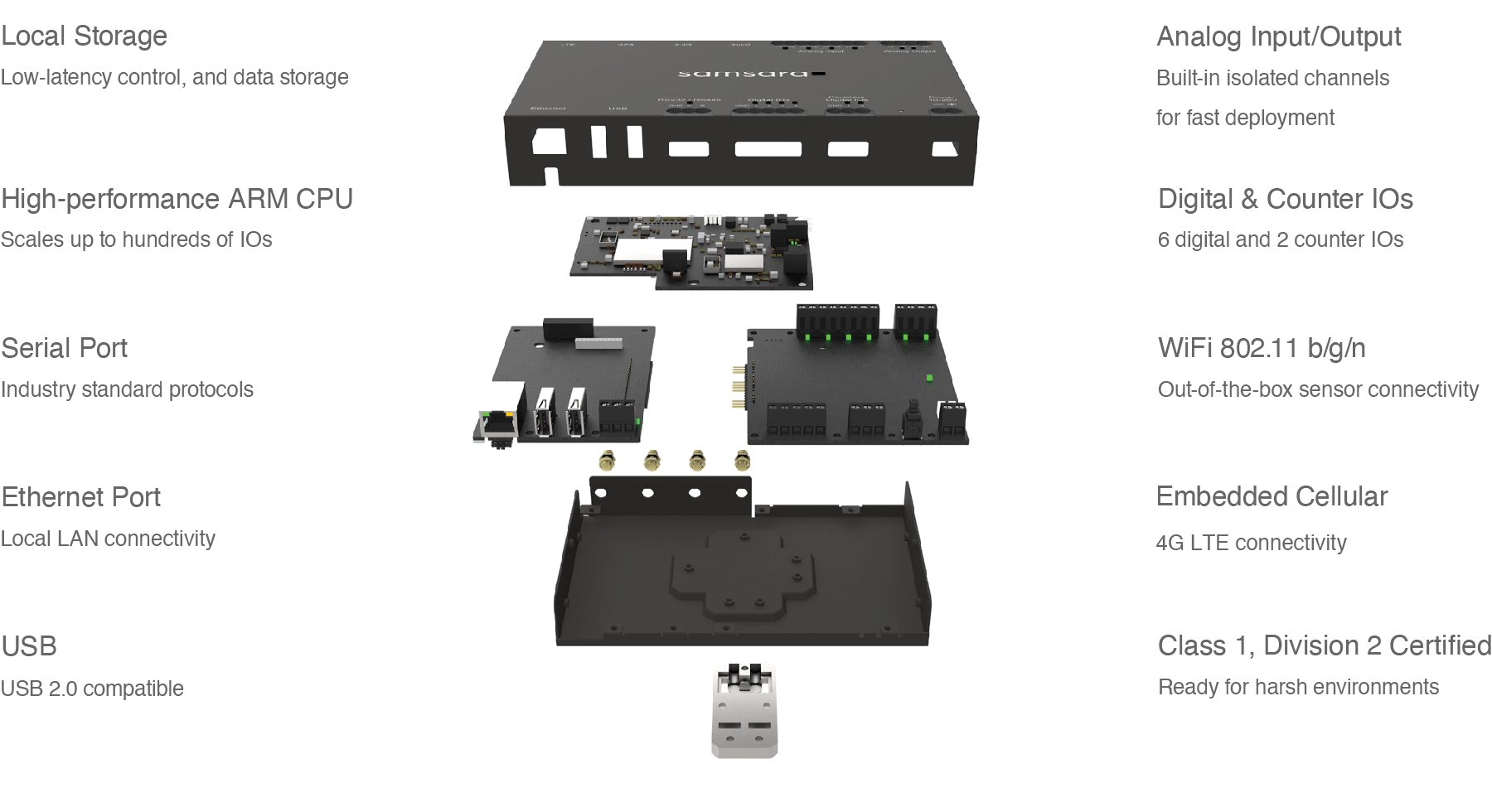

The IG21 was the Industrial Gateway that allowed Samsara to begin the Industrial sales flywheel. The goal for the HW team was to leverage previous hardware, and flexible manufacturing, such as laser NCT enclosures, to reduce lead time and capital costs. The IG21 accomplished this and lasted for several years before its iteration.