Samsara Equipment Monitoring

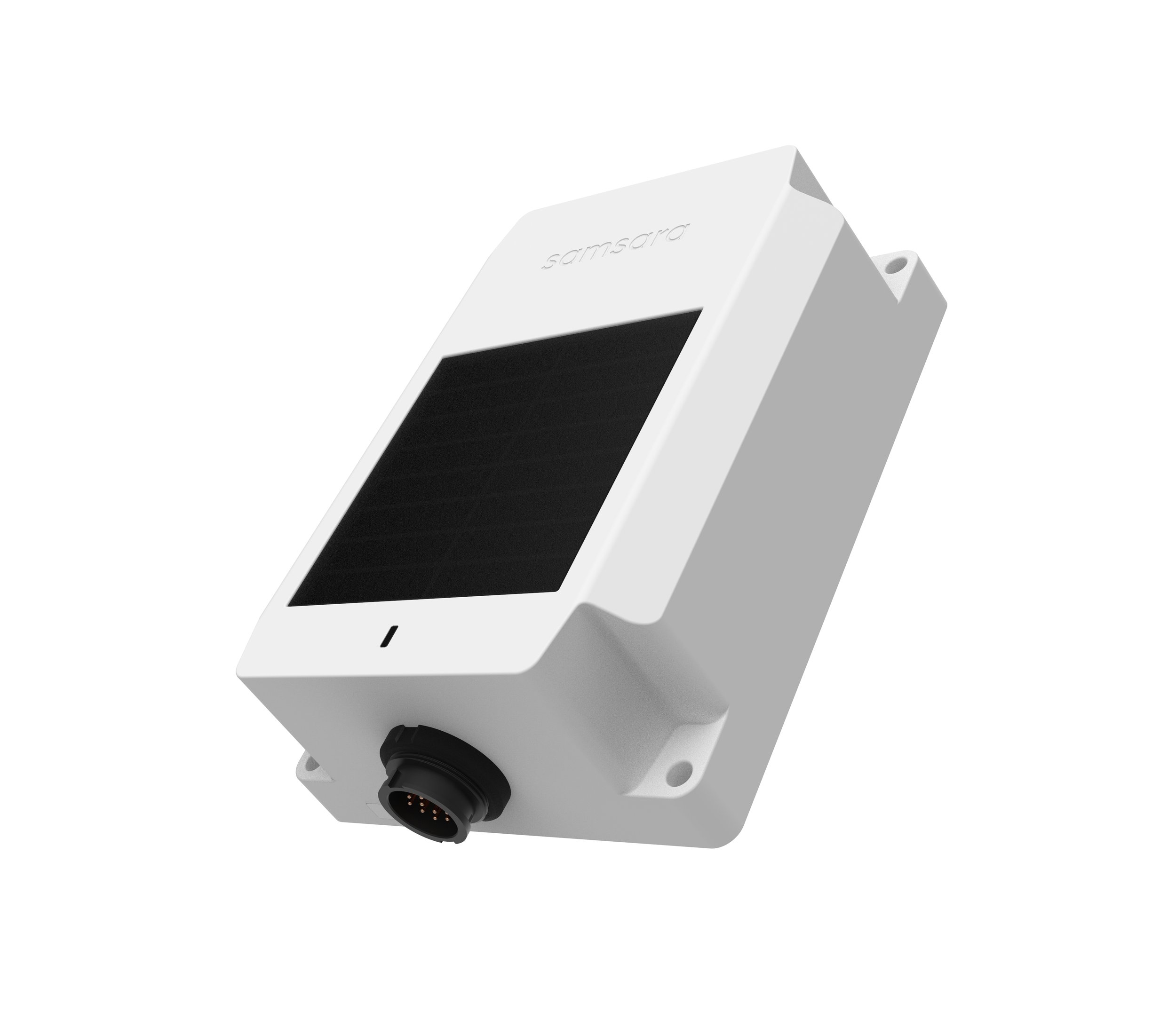

Samsara expanded their tracking offering beyond vehicles by introducing Equipment Monitoring. This allowed customers to track their equipment, optimize utilization, implement preventative maintanence and improve billing and job costing. To implement the equipment tracking product line, we needed to plug into a plethora of new machines, trailers and reefers, while also creating the most robust outdoor tracking device yet. The result was the AG series.